Hello pepole! But how is SpaceX possible? How can they go so fast from concept to launch?

Of course, it is great to see SpaceX as an emerging pioneer of space technology due to setting goals that seemed impossible. The answer is its ability to approach fast prototyping and stiff testing through flexible application of innovative technology, systemic work organization, and distinct engineering style.

Collectively, these factors alter traditional spaceflight timelines by compressing development time while allowing for testing, further development, and learning of unanticipated micro- and macro- issues at a much faster rate than conventional aerospace firms.

Let’s dive in!

The Hardware Behind SpaceX’s Fast-Paced, Full-up Prototyping/Testing Cycle

The Integration in Streamlined Engineering

Vertical integration is another great change driver that has been identified at the helm of SpaceX’s short development cycle. In contrast to most of its counterparts, most SpaceX components are created and produced by the company.

Such a strategy eradicates dependence on third parties and enables SpaceX to fully monitor quality, release improvements frequently, and reduce cycle durations.

In the same manner, SpaceX adopts the minimum human intervention in all aspects of the manufacturing process of its components and the operations of its launch vehicle, which eliminates potential errors and hastens monotonous processes.

Test rigs, for instance, those in rocket engines and avionics divisions, can perform multiple tests without manual cycles of equipment setup, reducing time.

3D Printing From Concept to Reality

In 3D printing, engineers can create a part on the computer, produce a working prototype, and test it within days.

It allows for multiple cycles of iteration and testing, which is key for any system – simple or complex – such as rocket engines. SpaceX can tweak components during production, allowing the company to improve designs within a shorter time frame.

Unlike when traditional manufacturing holds them to fixed designs, contractors, and materials, all of which extend the time it takes to go from one iteration to the next.

Simulation and Digital Twins

Digital simulations, such as advanced CFD and finite element analysis (FEA), allow SpaceX to find problems before the hardware is even built.

Even though the motivation for creating a digital twin of components is to be able to design and validate how parts and systems will respond in conditions of stress, high temperature, and vacuum, they do not have to be physical.

These simulations allow engineers to identify flaws, confirm materials’ appropriateness, and identify likely failure points. Thus, such a vehicle is not realized as a physical prototype that could take thousands of iterations to perfect at an astronomical amount of both time and money; rather, it is created in the form of thousands of simulations that could be analyzed on the computer without ever requiring the physical testing or manufacturing.

Iterative Testing “Fail Fast” Culture

The engineering concept at SpaceX is ‘fail fast.’ This involves undertaking frequent tests, analyzing the failures of the tests, reporting, and then improvising quickly. Thanks to such an approach, SpaceX is free to launch multiple prototype models and enhance its efficiency after each test. Instead of waiting for the perfect design, it launches it and learns from engineering and operational errors along the way.

For instance, the Starship prototypes have conducted many test flights at high altitudes, some of which have produced catastrophic consequences. Yet each test is equally an important source of information that helps when designing the next round and defining what was a success or a failure. This continuous cycle of experimentation and knowledge enables SpaceX to remain innovative and aggressively advance from failure to success in ways contrary to the industry standards of aerospace engineering.

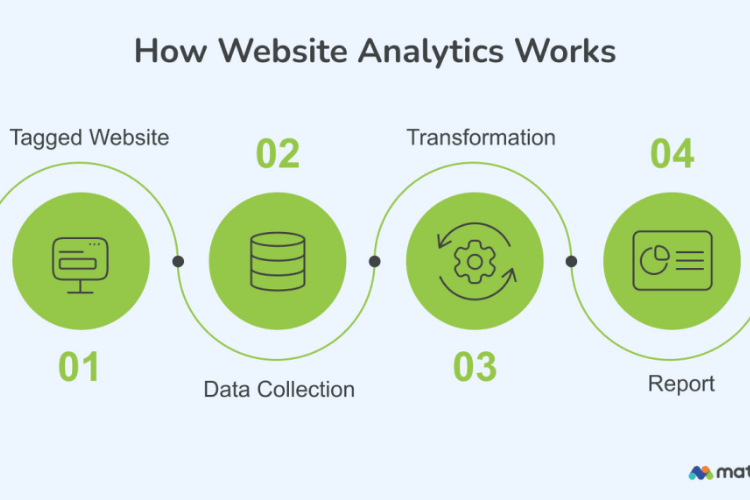

Big Data and Real-time Web Analytics

Big data is used actively in the context of testing at SpaceX. Data from over ten thousand sensors is accumulated simultaneously in test flights and engine firing operations. These data are processed quickly by sophisticated data systems that isolate any hardware or sub-optimal performance problem. Engineers at SpaceX can easily adapt new findings and recommendations as soon as a test is conducted, minimizing losses of invaluable development time, which slows down the process between tests.

Conclusion

The SpaceX organization is applying vertical integration, 3D printing, digital simulations, and the fail-fast methodology approach and is revolutionizing the aerospace industry through the development of new norms for prototyping and testing. SpaceX has established a process of prototyping and testing various architectural designs at regular intervals using services like 3-D printing, virtualization, and real-time analytical tools. This approach is revolutionizing historic aerospace time frames.

Could this pace within BIS rewrite the future of space exploration and commercial space travel?